Air Gauging

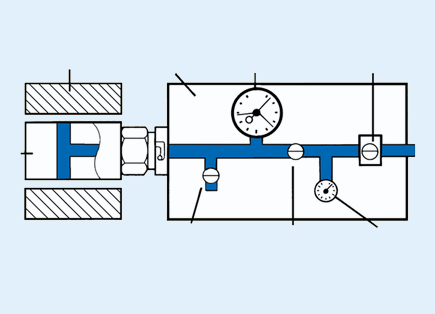

This is based on pressure change. Compressed air at a regulated pressure at 300kN/m2 flows into the gauge through a restriction into a small pressure chamber and then to atmosphere through two or more jets in an air plug, or air ring. Pressure in the chamber is extremely sensitive to changes due to variations of the gap between air plug and work piece and any changes in clearance are indicated by a suitable calibrated pressure gauge.

Air/Electronic Gauging

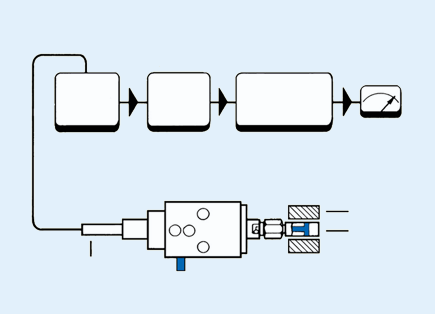

The simplicity, accuracy and versatility of the air gauging system can be further enhanced by utilising an electronic digital, analogue or LED column display unit. The air measuring head and electronic display are linked through an air/electronic converter.

Any variations in clearance between the measuring head and work piece are amplified by an electronic circuit and indicated on the display unit.

The Advantages of Using Air Gauging

Clear & Precise Measurement

Speedy measurement with excellent repeatability & highly visible readouts. Calibrated with upper & lower setting masters our system ensures both accuracy and linearity combined with simplicity.

Longer Lasting Equipment

No moving parts and non-contact with the work piece (eliminating unnecessary marking of workpiece) unlike electronic probes, give air gauges excellent longevity in use and low maintenance costs. For an even greater working life under severe conditions special coatings can be applied to our gauges.

Self-Cleaning at Gauging Point

The already filtered high pressure air used in our system removes any fluid or debris left by the machining process ensuring good clean points at which to gauge. Electronic probes may be affected by this.

Ease of Use by Unskilled Labour

Once installed & calibrated by skilled labour then the gauge can be used at ease by unskilled labour with no or minimum input required by the operative.

Diameters can be gauged from 1.0mm upwards

Multi-Gauging in One Hit

If required, depending on design and application multi gauging operations can be executed in one ‘hit’. For instance multi diameter gauging (2,3 or 4 of the same diameter or different diameters / features) can be completed at one occurrence saving both time & costs.

Gauging of Features

Thickness, ovality, taper, straightness, flatness, tri-lobing, squareness, centre distance, concentricity, square/oblong features etc. can all be gauged simply using air gauging.

Easy Connection to Computer

Via RS232 feeds from readouts statistical process control software can be used to interrogate the processes from uploaded data.

A Full Air Gauging Solution

Can be designed, engineered and produced in house from our premises in Redbourn. Try us?